- Home

- Eltra Elemental Analyzer

- TE Trace Sulfur/Nitrogen/Chloride Analyzer

- CHNSO Analyzer

- Coal Test Equipment

- Oil/Lubricant/Petroleum Analyzer

- Contact Angle Meter/tensiometer

- Electric Fluxer

- Food Analysis

- Furnace

- Spectrophotometer

- Viscometer

- UltraPure Water Purification System

- Laboratory Equipment Store

- Profile

- Contact

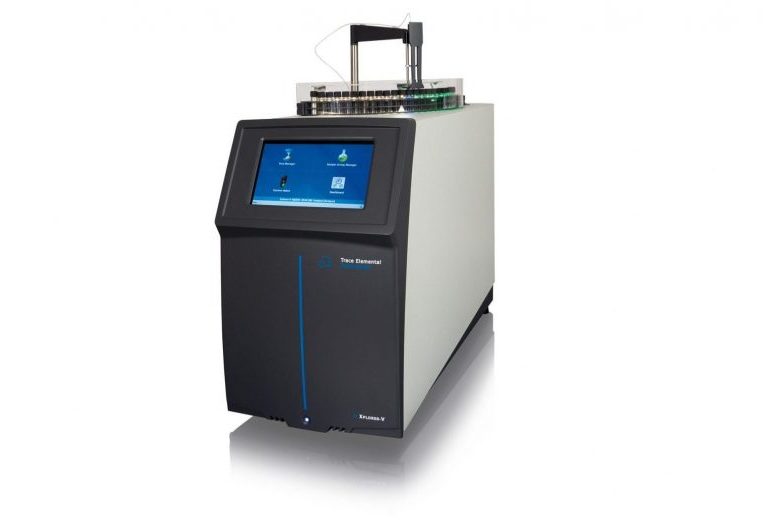

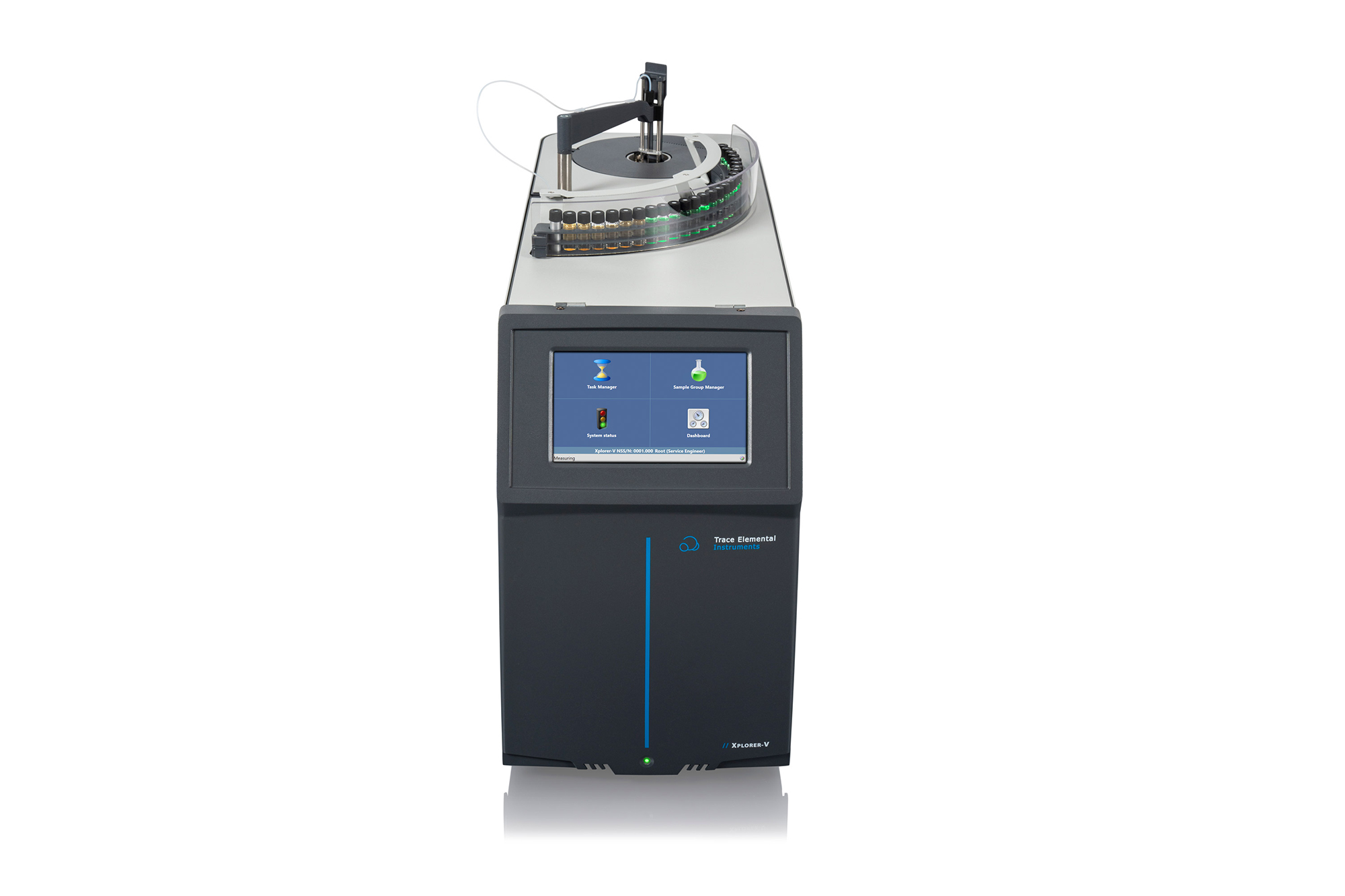

NITROGEN/ SULFUR ANALYER with Vertical Furnace

XPLORER-V NS

Next-Gen Nitrogen and Sulfur Analysis

The Xplorer-V is a fully automated Nitrogen and Sulfur analyzer that offers the most features out of the smallest footprint. Completely optimized for your (liquid) hydrocarbon sample analysis, offering fast combined TN/TS analysis, top detection performances, smart operation features, data-driven robustness, and a fully loaded method library. All in one single configuration.

The analyzer produces accurate results rapidly and suggests user actions based on extensive data collection. A solution you can rely on. The Xplorer-V is designed to provide the best analytical experience when running (liquid) hydrocarbon applications according to relevant international test methods, such as ASTM, DIN, ISO, and UOP.

Benefits

-Most Compact Analyzer on the Market

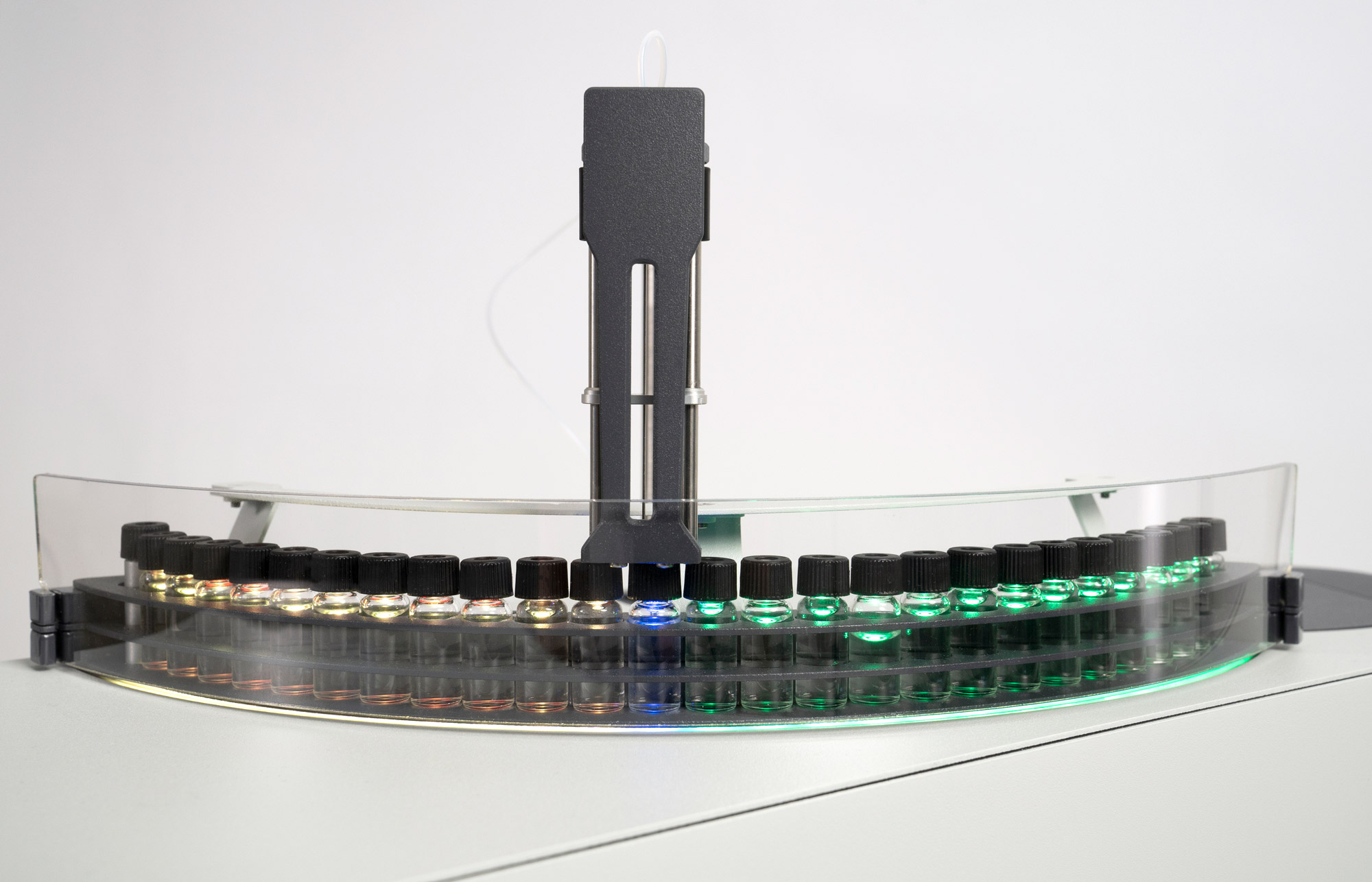

-Integrated 26 Position Autosampler LS-26

-Fast Analysis: 2 – 6 Minutes

-Xpro-V™ Combustion Tube

-Ultra-Low Detection Limits: 10 ppb (S), 10 ppb (N)

-Nitrogen Oxide Elimination Technology (NO-ET)

-Auto-Clean Function

-Easily Accessible Filters and Permeation Tube

-Data-Driven Robustness with TEIS Software Counter-Center™

-Instrument Performance Dashboards

-Operated through PC or Incorporated Touch Screen

Common applications

- Chemicals (e.g. Plastics, Aromatics, Olefins and Parafines)

- Refinery Products (e.g. Crude Oil, Naphta, Lubricants, Gasoline, Diesel Fuel, Fuel Oil)

- LPG and Gases (e.g. Pentane, Butane, Propane, Propylene)

Images

Background

Regulating bodies all over the world have set challenging low levels of allowed Sulfur and Nitrogen concentrations in organic fuels for the present and near future in order to protect the environment.

Oil refineries produce a wide range of air and water emissions that can be harmful to the environment. Some of the contaminants are present in the original crude oil, while others are a result of refinery processes and operations. Air emissions include sulfur dioxide (SO2) and nitrogen dioxide (NO2), which have to be monitored.

During the production process of oil products, nitrogen oxides (NOx) are formed in the gases of the furnaces, which are corrosive to steel. In addition, during catalyst reforming, naphtha is pretreated to remove contaminants like chlorine, sulfur and nitrogen which could poison the catalyst. Right before the end-product is sent to blending and storage, the oil product is treated once more to remove the last amounts of nitrogen and sulfur completely.

Refineries need to monitor and control the total nitrogen and total sulfur content in the feedstock. This is the only way to tune their processes at the highest level of efficiency and also important in order to protect the quality of fuels which leads to a cleaner environment.

Videos

International Standards

ASTM D5453, ASTM D6667, ASTM D4629, ASTM D7551, ASTM D7183, ASTM D7184, ASTM D5176, UOP 936, ISO 20846, UOP 987, UOP 981, NEN 17178